A wide variety of defects can occur when it comes to plastic injection molding. Bright and dull bands that spread out and repeat in a direction perpendicular to the flow direction are called flow line defects. Flow lines (or flow marks) can frequently happen for a range of causes and in various kinds of polymers. They negatively affect the plastic part's mechanical properties and surface finish quality.

What Are Flow Lines or Flow Marks Defects?

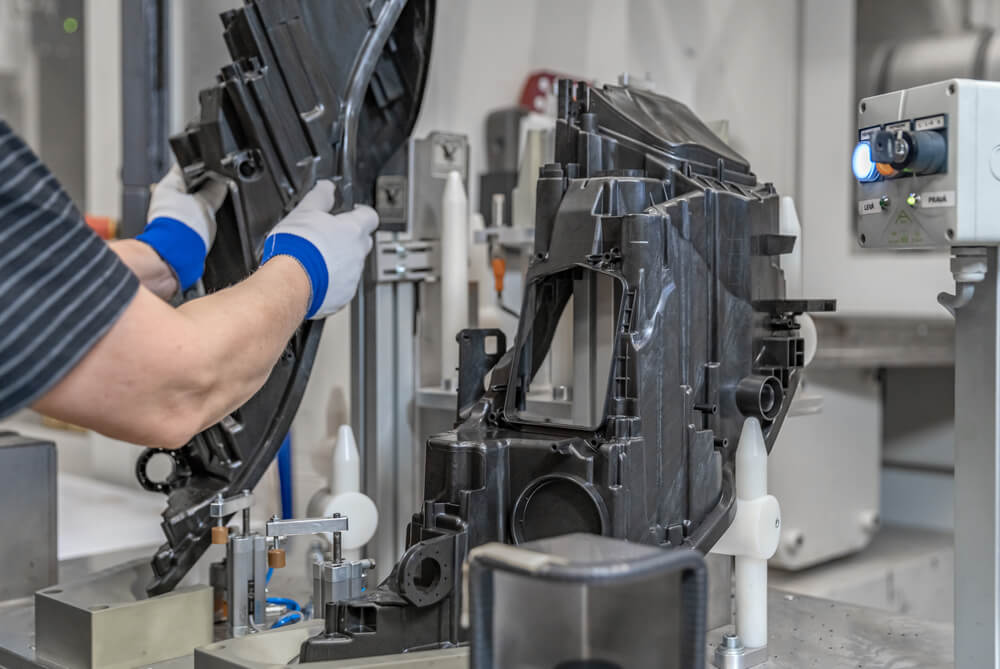

On the surface of a molded object, flow lines (also called flow marks) refer to the phenomenon that linear grooves or circular ripples showing the direction of material flow inside the mold cavity. They may also take the form of ring-shaped patterns when staying close to the mold's entry point, which is the plastic injection nozzle. Even though the majority of this type of imperfection does not damage the molded object's integrity or operation, a slightly distinct color showing an irregular material flow can diminish the aesthetic quality in customers' eyes.

Specifically, flow line defects can be classified into four typical types by the shape of the lines:

1. Snake lines

This is a serpentine flow line coming from the jet effect, and it is often created when the melt enters the mold cavity from the gate. When this happens, it can form the appearance of a snake line on the product's surface.

2. Wave lines

The main cause of wave lines is that the melt does not flow evenly into the mold cavity; it moves swiftly and slowly at different times. It is known as the wave line because it resembles waves on the product's surface.

3. Radiation lines

Often showing up only close to the gate location, the radiation line refers to the visible line on the product's surface created by the jet. This happens when the melting plastic flow enters the cavity of the mold.

4. Fluorescent lines

The shear stress, caused by melt flow, causes the product's surface to produce a shine that is strikingly similar to the body of a firefly, hence the name fluorescent line.

Potential Causes of Flow Lines in Injection Molding

As there are numerous reasons for this non-uniform material defect, the following sections will examine potential causes that result in flow marks from the aspects of the material, machine, mold conditions, and mold design.

Uneven Cooling within the Mold

Flow lines are frequently the result of changes in the plastic's rate of cooling, as the melt flows through the mold in various directions. They can also appear when manufacturing parts with different thicknesses since these lines result from thinner areas cooling before thicker ones.

This imperfection forms as more hot plastic flow past components that have already cooled and become sticky.

Although there are numerous causes of flow marks in injection molding, they are typically brought on by the plastic substance cooling unevenly. Therefore, it is advisable that the injection molding process should set up an air or water-cooling chiller to better monitor and control the temperature.

Improper Residence Time or Cycle Time

There are several elements to a cycle time, but flow marks will only appear if the melting time is longer. Before the injection operation finishes, the plastic pellets must be adequately heated to reach a molten condition in the machine's barrel. Try to extend the plastic pellets' heating time if noticing the defects.

Too Low Barrel or Nozzle Temperature

The heaters built into the barrel of the injection molding machine melts the resin pellets as they pass through the barrel and into the mold. The barrel has a front zone, center zone, rear zone, and nozzle at the end of the production line. To guarantee that the resin is properly melted for injection, the temperature of these zones should remain constantly high. If not, the resin would not melt fully and cannot force against the surface of the mold, which results in displaying flow lines.

Too Low Mold Temperature

When the mold temperature is too low, it can also lead to these marks since the material temperature drops quickly. As a result, the injection pressure and holding pressure cannot reach a high enough level to force the solidified layer on the mold surface.

Sizes of Sprue, Runner, and/or Gate

The flow resistance will rise if the sprue, the runner, or the gate size is not spacious enough. Additionally, if the injection pressure is insufficient, the melt front will advance more slowly, which causes the plastic to turn cold. This action will prevent the injection pressure and holding force from pressing the solidified layer against the mold surface. The result is leaving flow marks in the direction of the melt flow.

How to Avoid Flow Marks for Better Surface Finish?

A straightforward solution is to raise the mold temperature. A water or oil mold temperature controller can achieve this by increasing the mold temperature and stabilizing the high temperature for the material at the desired level. Being an expert in molding technology, Flying Tiger can provide not only oil but also oil and water temperature controllers for different materials and temperature ranges. After that, high injection pressure and holding pressure can be used to solidify the layer on the mold surface until the product is molded to prevent flow lines.

Secondly, the injection pressure is directly proportional to the injection speed. High pressure is associated with the high-speed flow. Because the molten material has more time to cool at low rates, increasing the speed of material flow is crucial in plastic injection molding. To improve flow and delay premature cooling, we may need to increase the nozzle diameter.

However, the plastic molding production line is strongly linked. Fixing at a single point might not be the most effective and efficient solution that businesses look for. Instead, focusing on having a good mold design is the key to ensuring material flow goes smoothly while being kept at the proper temperature.

Control Mold Temperature Better to Prevent Flow Lines

Maintaining a constant temperature is more complicated because both machine and the mold produce heat, and drastic variations to either one might result in worse flaws. Along with flow marks, pressure, which is a factor causing many other types of defects or imperfections, is closely tied to temperature. Most materials will have suggested mold temperature ranges, but keep in mind that when plastic moves away from heat sources, it will naturally cool down.

Therefore, using a mold temperature controller is highly recommended. The goal of the mold temperature controller is to regulate the desired temperature to prevent flow lines and other imperfection marks.

Partner with a vendor having decades of experience in the industry—Flying Tiger knows how to troubleshoot common defects in the injection molding process, including the flow line causes and solutions. These insights will help you come up with an optimal plastics manufacturing process. Adopt our auxiliary equipment to ensure the finished products are both aesthetically and structurally sound. Contact Us for more information!

Back