FEATURE

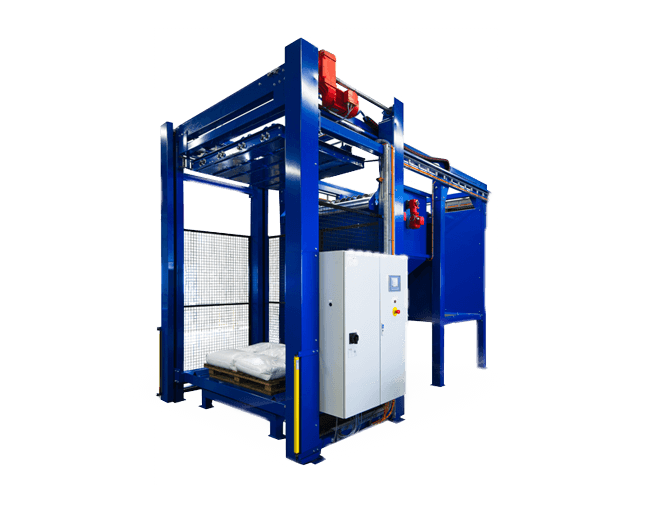

- Expandability: possibility to

- Add a bag compacter

- Add a pallet stacker

- Implement in complex control system with full process control - Flexibility (additional options, executions can be discussed)

- Robust execution

- Separated steady movements

- Electrical lift executes vertical movement

- Shuttle executes horizontal movements

DESCRIPTION

- With the fully automatic bag emptying machine, granulate bags of 25 kg can be opened and emptied into a receiving bin.

- The capacity of the machine is between 10 and 15 tons of granules per hour.

- Emptying is better than 99.98%!

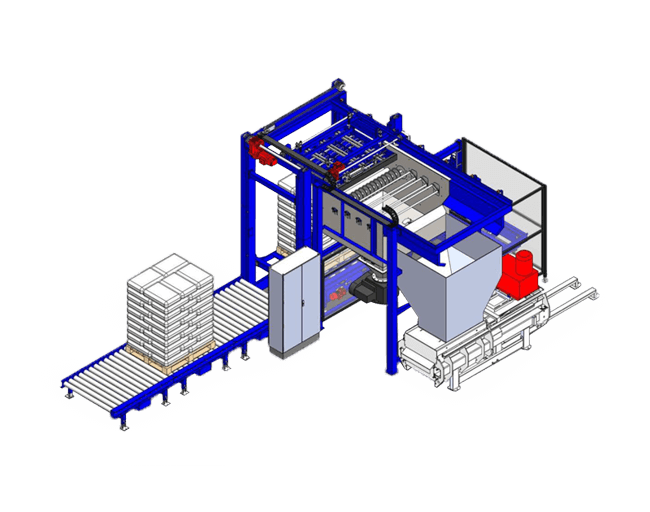

- It is also possible to transport or drop the empty bags (in)to a bag compactor or baler.

- The granulate in the receiving bin is transported from the bin by means of a granulate pump into the pneumatic transport system.

- This system provides a durable and reliable transport to storage silos.

Alternative designs and extra options

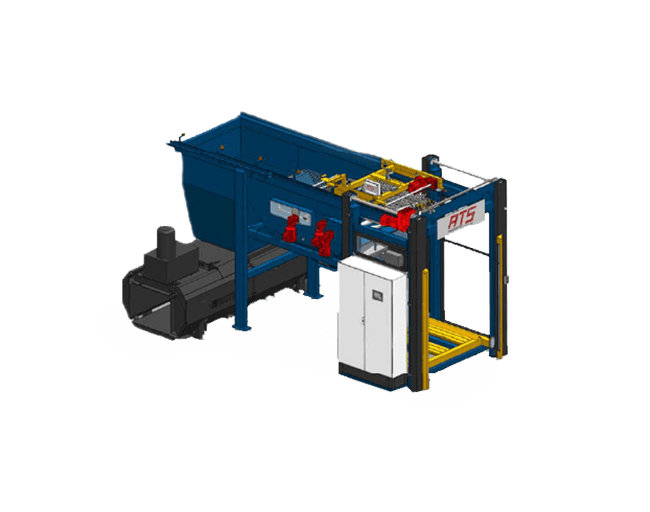

- XL unit: Suitable for dumping granulate into containers, big bags, octabins or truckloads;

- Automated cleaning: This machine can clean itself after a batch, so it is immediately ready for a different product

- Automatic pallet transport (in and out)

- Integrated palletstacker for stacking the empty pallets

- Integrated bag compactor or baler for the empty bags

Specification of Bag Emptying Machine

- Pallet dimensions: 1300mm x 1100mm (to be confirmed by customer)

- Max. intake width: approx. 1400 mm

- Pallet weight: approx. 1600 kg

- Pallet height: max. 2200 mm (to be confirmed by customer)

- Stacking: 5 bags per layer, stacked 3 by 2 in alternating directions, 11 layers

- Capacity: approx. 15t/h (granulate) with >99,98% discharge

- Supply voltage: 3x 400V, 50Hz + earth

- Protection rating: IP55

- Control voltage: 24 VDC

- Air consumption:10 Normal-liter / cycle

- Air conditioning: 6 bar dry conditioned air

- Finishing: Frame: powder coated in RAL color

- Total Load: 6.85 KW