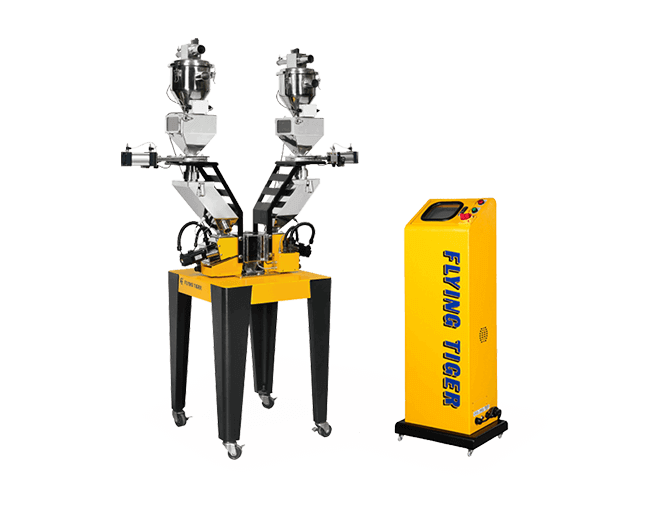

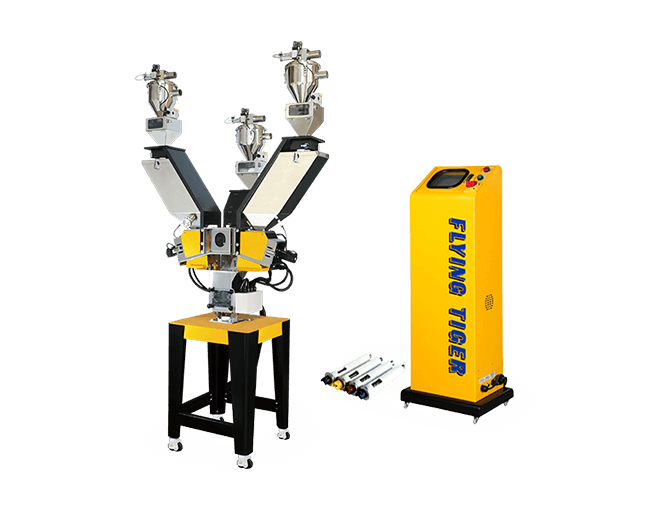

Gravimetric Dosing Blender

Flying Tiger gravimetric dosing blender (gravimetric blender) embodies innovations that increase the efficiency of production, feature improved design, high-performance components, and twin cone gates designed for perfectly dosing weight control.

Not only can Flying Tiger gravimetric blender have a precisely dosing amount but also equipped with a unique design batch blender to mix up to 8 materials.

Multiple cone gate design for fast and accurate dosing design.Dosing stating can be expended up-to 8 stations.

PLC control for easy programing for individual customer. Gravimetric control increases dosing accuracy to 99.9%.

FEATURE

- Simultaneous coloring automatically for saving working hours and storage space.

- The twin cones gates are designed to control the batch dosing weight of raw material exactly.

- Vertical mixer design without residual material for material changeover easily.

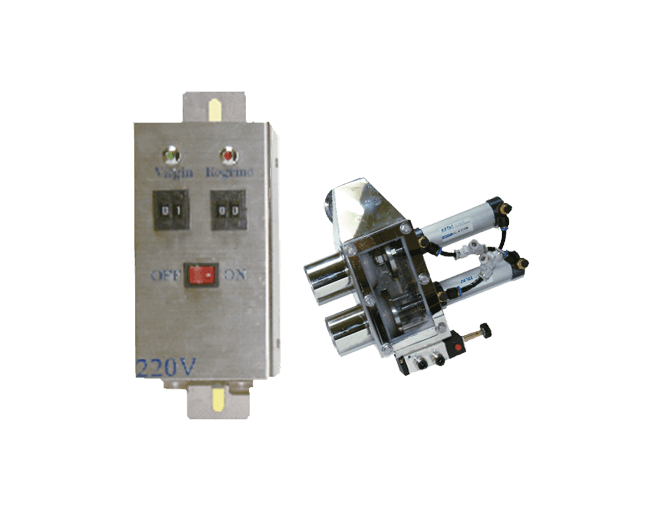

- Equipped with colorful human-machine screen and PLC controller, also it can built-in material conveying system for monitoring operational status easily.

- All the dosing stations are equipped with material shortage alarm and they will stop to wait material supply automatically if any dosing station is lack of material.

Specifications

|

Model |

KGDB-100 |

KGDB-250 |

||||||

|---|---|---|---|---|---|---|---|---|

|

2G |

3G |

4G |

2G |

3G |

4G |

|||

|

No. of station |

2 |

3 |

4 |

2 |

3 |

4 |

||

|

Capacity |

KG/HR |

120 |

110 |

100 |

290 |

270 |

250 |

|

|

Weight bin |

KG |

3 |

5 |

|||||

|

Dosingmethod |

Two cone gates |

2 |

3 |

4 |

2 |

3 |

4 |

|

|

Control type |

7.0" Colorful human-machine & PLC control | |||||||

|

Mixer |

KW |

0.4 |

||||||

|

Buffer tank |

LITER |

15 |

25 |

|||||

|

Compressed air |

MM |

ø5*8 MM, at 5 KG/CM² |

||||||

|

LPM |

60 |

|||||||

|

Total load |

KW |

0.4 |

||||||

|

Dimension |

Machine |

CM |

68*68*155 |

68*68*168 |

||||

|

Controller |

46*34*113 |

46*34*113 |

||||||

|

Approx. |

Machine |

CM |

65 |

80 |

||||

|

Controller |

40 |

40 |

||||||

|

Options |

1.Central material receiver 2.Central loader 3.Auto-cleaning vortex cyclone |

|||||||

|

Remarks |

1.These specifications are for reference only. We reserve the right to change specifications without prior notice |

|||||||

|

Model |

KGDB-600 |

KGDB-1000 |

||||||

|---|---|---|---|---|---|---|---|---|

|

2G |

3G |

4G |

2G |

3G |

4G |

|||

|

No. of station |

2 |

3 |

4 |

2 |

3 |

4 |

||

|

Capacity |

KG/HR |

800 |

700 |

600 |

1500 |

1200 |

1100 |

|

|

Weight bin |

KG |

10 |

20 |

|||||

|

Dosingmethod |

Two cone gates |

2 |

3 |

4 |

2 |

3 |

4 |

|

|

Control type |

7.0" Colorful human-machine & PLC control | |||||||

|

Mixer |

KW |

0.4 |

||||||

|

Buffer tank |

LITER |

50 |

100 |

|||||

|

Compressed air |

MM |

ø5*8 MM, at 5 KG/CM² |

||||||

|

LPM |

60 |

|||||||

|

Total load |

KW |

0.4 |

||||||

|

Dimension |

Machine |

CM |

70*70*197 |

116*116*270 |

||||

|

Controller |

46*34*113 |

46*34*113 |

||||||

|

Approx. |

Machine |

CM |

95 |

125 |

||||

|

Controller |

40 |

40 |

||||||

|

Options |

1.Central material receiver 2.Central loader 3.Auto-cleaning vortex cyclone |

|||||||

|

Remarks |

1.These specifications are for reference only. We reserve the right to change specifications without prior notice |

|||||||

|

Model |

KGDB-2000 |

|||||||

|---|---|---|---|---|---|---|---|---|

|

2G |

3G |

4G |

||||||

|

No. of station |

2 |

3 |

4 |

|||||

|

Capacity |

KG/HR |

2600 |

2200 |

2100 |

||||

|

Weight bin |

KG |

40 |

||||||

|

Dosingmethod |

Two cone gates |

2 |

3 |

4 |

||||

|

Control type |

7.0" Colorful human-machine & PLC control | |||||||

|

Mixer |

KW |

0.4 |

||||||

|

Buffer tank |

LITER |

200 |

||||||

|

Compressed air |

MM |

ø5*8 MM, at 5 KG/CM² |

||||||

|

LPM |

60 |

|||||||

|

Total load |

KW |

0.4 |

||||||

|

Dimension |

Machine |

CM |

116*116*288 |

|||||

|

Controller |

46*34*113 |

|||||||

|

Approx. |

Machine |

CM |

160 |

|||||

|

Controller |

40 |

|||||||

|

Options |

1.Central material receiver 2.Central loader 3.Auto-cleaning vortex cyclone |

|||||||

|

Remarks |

1.These specifications are for reference only. We reserve the right to change specifications without prior notice |

|||||||