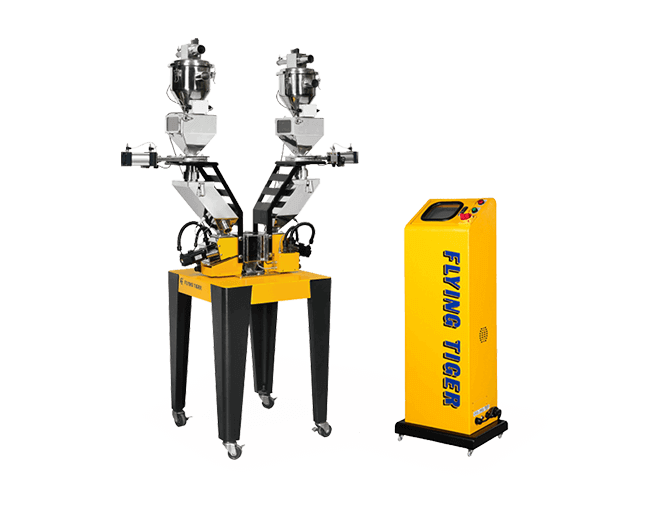

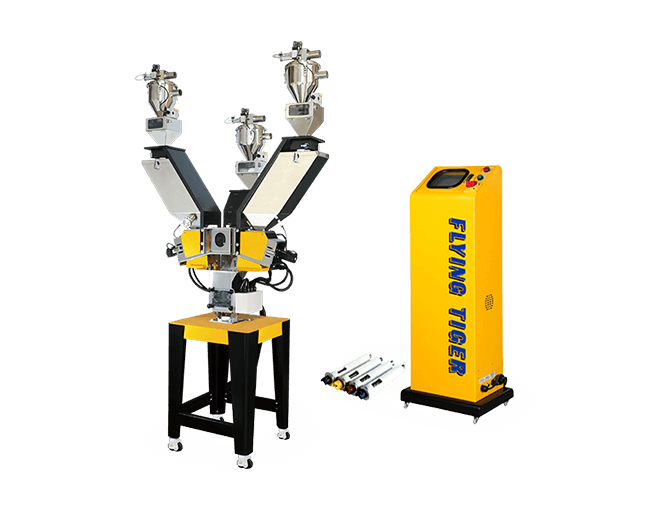

Loss-In-Weight Dosing Blender

Isolated loss-in-weight detective for each station, servo motor controls stable and accurate RPM between 1~1000.

Material loading and dosing can be operating simultaneously. The dosing station can be expended up-to 6 stations.

PLC control for easy programing for individual customer. Loss in weight control increases dosing accuracy to 99.9%.

FEATURE

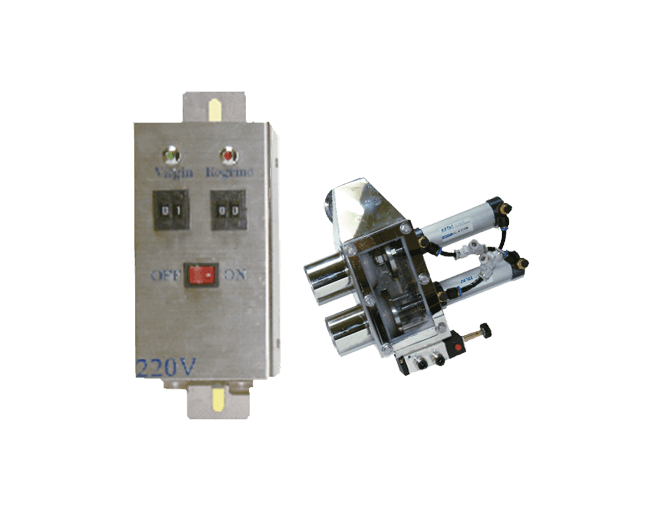

- Isolated loss-in-weight detective for each station, servo motor controls stable and accurate RPM between 1~1000.

- Loss-In-Weight , PLC and color-touch-panel create user friendly interface. Auto-Calculate the most perfect RPM to ensure stable and accurate dosing.

- All the dosing stations are designed for continuous dosing system they will be ON / OFF together according to the material component to keep mixing ratio consistently anytime.

- Adding a small mixer to ensure complete mixing of the materials.

SPECIFICATIONS

|

Model |

KLIW-2 |

KLIW-3 |

KLIW-4 |

KLIW-5 |

KLIW-6 |

|

|---|---|---|---|---|---|---|

|

Material Station |

SET |

2 |

3 |

4 |

5 |

6 |

|

Capacity |

Kg/Hr |

MAX 1200 |

||||

|

Control Type |

7" Color Touch Panel, Loss-In-Weight and PLC Control |

|||||

|

Dosing Motor |

TYPE |

Servo Motor, 220V, 1Phase |

||||

|

RPM |

1~1000 |

|||||

|

Mixing Motor |

KW |

0.2 |

||||

|

Max Power Consumption |

KW |

1.1 |

1.5 |

1.9 |

2.3 |

2.7 |

|

Dimension |

Screw ø6~ø15 |

30*150*67 |

90*150*67 |

150*150*67 |

128*141.5*68 |

|

|

Screw ø30~ø60 |

53*229*127 |

141*229*127 |

229*229*127 |

261*237*127 |

||

|

Controller |

45*35*115 |

58*39*115 |

||||

|

Approx. Weight(KG) |

Screw ø6~ø15 |

51 |

71 |

92 |

120 |

141 |

|

Screw ø30~ø60 |

98 |

142 |

184 |

240 |

282 |

|

|

Controller |

40 |

60 |

||||

|

Optional Dosing Screw |

|||||||

|---|---|---|---|---|---|---|---|

|

Dosing Screw |

MM(OD) |

ø6 |

ø8 |

ø15 |

ø30 |

ø45 |

ø60 |

|

Diameter |

MM(ID/OD) |

12.7/17 |

15.6/19 |

27.7/33.3 |

39/41.8 |

54.5/60.5 |

85.9/88.9 |

|

Dosing Capacity |

Gram/Turn |

0.28 |

0.50 |

2.10 |

4.10 |

28.90 |

145.80 |

|

Dosing Capacity |

Kg/Hr |

0.01 ~ 3 |

0.03 ~ 30 |

0.13 ~ 126 |

0.30 ~ 246 |

1.74 ~ 1,734 |

8.75 ~ 8,748 |

|

Hopper Tank |

Liter |

6 |

6 |

6 |

15 |

30 |

60 |

|

Load Cell |

Kg |

15 |

20 |

20 |

30 |

75 |

100 |

|

Dosing Motor |

KW |

0.2 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

|

Color |

Type |

White |

Green |

Red |

Blue |

Black |

Gray |

|

Options |

1. Central Material Receiver 2. Central Loader 3. Central Material Conveying System |

||||||

|

Remarks |

1. Pls. calculate dosing station by material type, quantity, and characteristics. |

||||||